30+ Years of Revolutionizing the Industry

30+ Years of Revolutionizing the Industry

Here at Fabspeed Motorsport, we are dedicated to delivering our customers the highest quality performance upgrades with the industry’s best lifetime warranty. We have over 30 years experience designing, engineering and installing high performance exhaust systems, air intake systems and ECU tuning for the world’s most coveted exotic cars. All of our products are designed and engineered right here in Fort Washington, Pennsylvania by our very skilled and passionate fabricators.

Mission Statement

Our sole mission is to design, engineer, and provide the world’s finest performance products and tuning for sportscars tailored to the desires of our customers. Our dyno-developed, racetrack and road tested upgrades curate a superior symphonic sports car sound and the greatest performance gains known to the world-wide sports car community, backed up by a Lifetime Warranty.

Key Objective:

We strive to make quality and performance personal. With 30+ years of experience, millions invested in CNC manufacturing equipment, and a drive for performance, results, and continual improvement, we can be sure you are getting exactly what you need to make your experience unique. If we don’t make a product you are looking for, our objective is to research, design and engineer a product that compliments your unique lifestyle.

CORE VALUES:

-

Providing an excellent customer experience in quality, reliability, performance, service, and sports car sound.

-

Continuously improve, refine and test our existing product line brought to you through 30+ years of innovation to further revolutionize the industry.

-

Excellent, responsive and loyal customer service on an international scale. Our experts provide a wide knowledge base appreciated by car enthusiasts worldwide, and we strive to be more reachable and interactive in all areas of the enthusiast community.

-

While upholding the highest standard of quality and in-house craftsmanship, we work with a sense of urgency to provide customers with extraordinary performance products as soon as possible. We maintain the industry’s best practices, and perfection can often take time.

-

Actively giving back to the community is very important to us. This includes charity drives, blood drives, disaster relief and content communities for enthusiasts. Fabspeed strives to be as environmentally friendly as possible by recycling all available materials. Fabspeed advises retaining and installing catalytic converters to protect the environment unless all out racing competition is the objective.

Fabspeed's World Headquarters

Fabspeed Motorsport is located in Fort Washington, PA, right here in the United States of America. Our 26,000 sqft. facility hosts car clubs like Porsche club of America, Ferrari, Mclaren, Lamborghini and more.

We design, engineer, dyno develop, street & race test 100% of our products. Fabspeed collaborates with Race Engine builders and Tuners from Italy, Germany, and USA to develop the Ultimate Performance parts. Fabspeed crafts systems in aerospace austenitic stainless steel, titanium, and carbon fiber for our passionate worldwide audience.

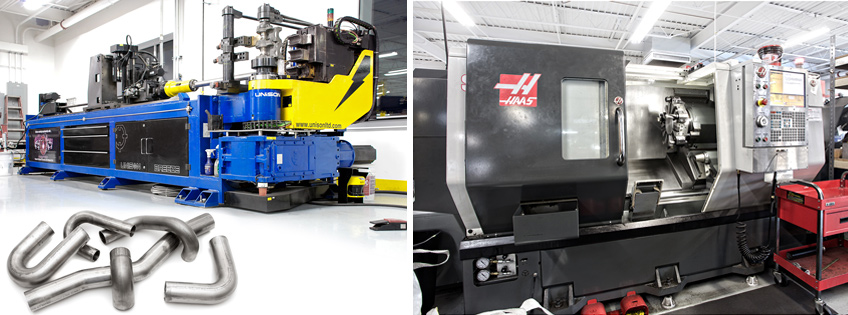

UNISON LIMITED UNITED KINGDOM

First corner of our impressive shop has our all electric CNC mandrel bender. We bend our own tubing in house to precision tolerances, ensuring quality control and craftsmanship across the board. This machine is used by Boeing, Airbus, Grumman, Dassault Aviation, and more!

BYSTRONIC

This all electric precision CNC Press Brake imported from Germany is used to bend and form precision stainless steel and titanium brackets.

FLOW CORPORATION WATERJET MACH 5

Fabspeed has waterjet technology to design and cut precision parts in-house for ultimate quality and shortest lead times to serve our wonderful customers.

The market for CNC waterjet cutting machines started many years ago serving mission critical aerospace engineers and contractors looking for non HAZ, Heat Affected Zones. Companies like Boeing, Lockheed, Grumman Aerospace, Rockwell International all defense contractors have flow jets.

HAAS CNC VF2 VERTICAL MILL

Fabspeed has a new CNC precision machining center from world famous HAAS corporation. CNC machining gives Fabspeed the in-house capability & advantage to offer ultimate traceable quality and performance to our customers.

HAAS CNC ST20 HORIZONTAL LATHE

Fabspeed second CNC precision machining center from world famous HAAS corporation. CNC machining V band flanges are made with this for Ferrari, McLaren, Porsche and Lamborghini. HAAS is a leader in CNC machine tooling worldwide and even has a HAAS CNC Formula 1 team.

FARO ROMER CMM Laser Arm Scanning System

Fabspeed has an in house advantage to acquire super accurate measurement data to reverse engineer parts and systems. This equipment is essential in developing super accurate fixtures, jigs and parts for delivering precision and quality to customers. Traceability, engineering validation, quality, and accountability are not outsourced and compromised like most companies. Solidworks and Fusion CAD employed.

FUSION 3D

A 3D dimension printer is employed so new parts and theories for maximum performance and sports car sound can be tested and explored. This gives us a competitive edge to cater to more niches and the newest products for customers worldwide.

LASER ENGRAVING

Our laser engraving sintering machine to burn in part numbers and Custom Engravings, graphics and more for our worldwide customers. Personalized performance and quality are highly valued at Fabspeed, and deep laser engraving lasts a lifetime, just like our warranty!

DYNO-JET ALL WHEEL DRIVE 4WD Model 424xLC2

Fabspeed invested in sophisticated Dyno technology to acquire before and after horsepower and torque. The design engineering team doesn’t quit until maximum power is achieved with superlative sports car sound and reliability. Our weather center is equipped so no manipulation is possible to ensure real world documented gains from all of Fabspeed’s track and road tested products. While testing different products or to upgrade customers existing aftermarket exhausts, we found many competitors exhaust systems, notably from other US Germany, Italy and China often lose heaps of horsepower.

MILLER WELDING SYSTEMS

Fabspeed’s skilled craftsmen use the latest TIG equipment (including back purging) to offer the finest quality and longevity in the industry. A key distinguishing indicator of skipping these imperative steps include brushing or sandblasting welds to camouflage poor quality. This is why we would never hide our beautiful TIG welds from our customers.

Fabspeed has Miller training staff come to our facility for continual improvement and ensure we are maintaining the best practices, especially with new staff members. Fabspeed hires and trains multiple students from technical schools and trade schools to give back to the community.

Canada

Canada

Euro

Euro

Australia

Australia

Pound

Pound

Peso

Peso

Singapore

Singapore

Bahraini Dinar

Bahraini Dinar

Malaysian Ringgit

Malaysian Ringgit

Qatar

Qatar

Russian Ruble

Russian Ruble